Allen Bradley vs Siemens: What’s the difference between these PLC tools?

Though it may be hard to believe that industrial automation has been around for nearly 70 years, what’s harder still is that technology is continually finding new and innovative ways to improve production capabilities and process efficiencies. Of the very long list of industrial technologies that emerged from what has come to be known as the third industrial revolution, the Programmable Logic Controller (PLC) is arguably one of the most impactful. The fact that this seemingly nondescript industrial box could possibly reign supreme over other transformative technologies developed in the 50’s and 60’s – mainframe computing, personal computers, semiconductors and others – speaks volumes to what PLCs have meant (and continue to mean) for manufacturing in the 20th and 21st centuries.

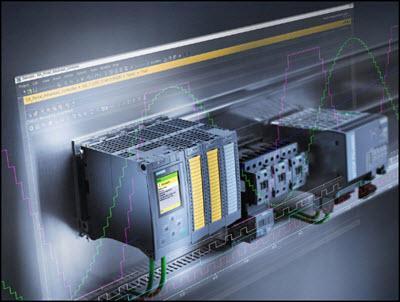

Like anything else, not all PLCs are created equal; each PLC on the market today has its own list of features and benefits. Two such PLCs, Rockwell’s Allen-Bradley and Siemens are two of the world’s most widely used PLCs – and while each device is undeniably an industry staple there are a number of key differences between the two of them. Let’s take a look at how they stack up.

Performance and Usability

When it comes to technology that could revolutionize operations on the factory floor, performance is going to command the lion’s share of attention. Unfortunately, making a decision between Allen-Bradley and Siemens based purely on performance isn’t easy; they’re both pretty evenly matched when it comes to speed, reliability, and output. Instead, things like ease of operation and integration are often the main points of differentiation that need to be considered.

There’a a lot to be said for ease of use and a user-friendly interface. The Allen-Bradley PLC is known for boasting both of these qualities and that makes this Programmable Logic Controller an appealing investment for any manufacturer. Ease of use means that even a relatively untried PLC technician without extensive programming experience can still make use of an Allen-Bradley PLC – but the ease of use doesn’t stop there. Debugging an Allen-Bradley PLC arguably takes less time and effort than it does with a Siemens PLC.

Further, Allen-Bradley PLCs communicate effectively with third-party devices, and can import and export tags from Excel to Human Machine Interface (HMI) or SCADA databases.

Having said all that, ease of use isn’t always the most important criteria depending on the experience level of the technician and the intended application. Siemens allows for their PLCs to be heavily programmed and customized to suit particular business needs. Naturally, this implies that a more robust computer programming background will be needed in order for a technician to effectively make use of and maintain a Siemens PLC, but the opportunities such customization lends itself to cannot be understated.

Hardware

If, after reading the last section you feel more strongly towards Allen-Bradley than Siemens or vice versa, you may want to reserve judgement for a little while longer. While the general consensus is that Allen-Bradley PLCs are the more user-friendly solution of the two, they can fall a little short in terms of ease of installation when compared with Siemens.

When installing an Allen-Bradley PLC you’ll also need to connect the Allen-Bradley power supply, rack, and additional cards for safety communication ports. Siemens PLCs on the other hand, can be plugged into most standard 24V DC power supplies and come with built-in safety communication ports. Lastly, Siemens PLCs come with built-in protocols that meet European standards (ASI, Profinet, Profibus) whereas Allen-Bradley PLCs come with American protocols (EthernetIP, ControlNet, DeviceNet, etc.).

Support

Support availability is an important feature to consider when purchasing a PLC. Siemens offers 24/7 post-sales technical support, field service, and spare parts every day of the year, for a number of different products including anything that falls under their Process & Factory Automation category. Rockwell also offers 24/7 technical support for their products with 365-day availability but is less comprehensive than what Siemens offers, and the level of free support is dependent upon the amount of hardware installed. In either case, the level of support that you feel comfortable with could be an important factor when making the buying decision.

Which is the winner?

Admittedly, it’s easy to pick one PLC based on one feature or another, but it’s more important to look at the entire package – ease of use and integration, after sales support, etc. when making the buying decision. Ultimately, the right PLC is the PLC that checks the most boxes for the given application.

Determining a “winner” based on nothing more than popularity will actually depend on where you work. Siemens PLCs are hands-down the most popular of the two in Europe, which makes sense, given that Siemens AG happens to be the largest industrial manufacturing company on the continent. In North America, Rockwell Automation’s Allen-Bradley is by far the more popular PLC provider.

Learn more about factory automation via Rockwell PLCs by checking out George Brown’s PLC technician training program.