Intro to Writing a PLC Program in 4 Simple Steps

PLC is short for “programmable logic controller.” It’s essentially a digital computer commonly used in industrial electro mechanical processes for automation. This includes controls for systems such as amusement park rides, lighting and assembly lines.

Writing a PLC program

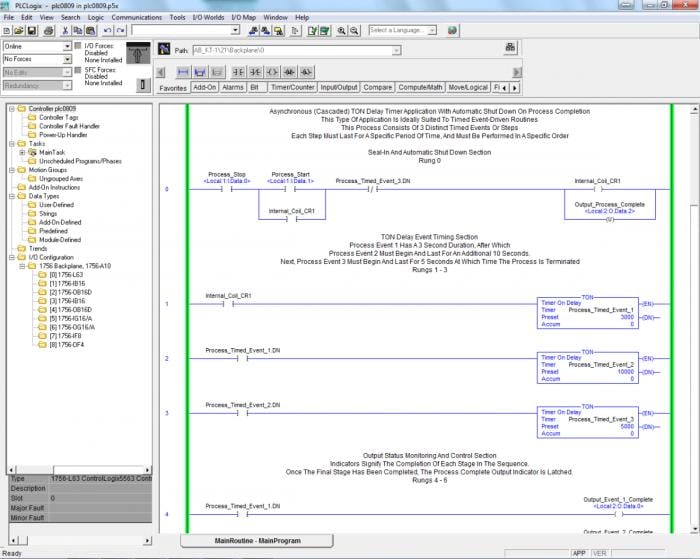

When it comes to writing a PLC program, there are a variety of methods. A common one is ladder logic, which involves a set of course of action to use in PLCs. These actions play a significant role in control systems and in updating outdated circuits. A useful way to remember them is to picture them as the blueprints for the program’s foundation.

The ‘frills’ can always be added on after once one has a firm understanding of how they work. These ladders have become more complex with the rise of automation and are often used in conjunction with other tools and computers to find the best method to complete a task.

Although writing a PLC program is a highly technical process, it can be understood in four simple steps:

Step 1. The machines operate in cycles, which are in turn a series of lines of code and sequences. You will want to define the sequences prior to writing any code in order to have a better understanding and plan of how to proceed.

Step 2. You will want to use the programming ladder to begin building the program. If you are unsure of what to do next, the best thing that you can is to conduct further research to increase efficiencies in your workflow. You will want to include added instructions and function blocks in order to make sure the machines are set for the long term.

Step 3. The controls and functions of a machine will vary according to the task it will carry out, but each cycle will require the ability to start, pause, and stop. Work on the sequences in easily managed sizes and then figure out what the trigger of each sequence will be.

Step 4. By the time it is completed, the sequences must be readable and with a clear operation sequence. They must be in order as well, with the top being the start and gradually working down with the bottom being the end of the program logic.

Also, make sure that your code isn't scattered, because that will only cause more issues for everyone involved in the long run. The program should also always return itself to its initial state so that it can run again if necessary.

Needless to say, there’s a lot more to know when it comes to writing PLC programs. It can be a complicated language to learn, but a very important one once you begin to master it. Properly-written code and a well laid-out process is the best way to ensure that every issue which arises can be solved. This is one of the most important notes for any stage of the cycle.

Modes

Another terminology to be familiar with are modes. There are primarily two kinds of modes, automatic and step. Automatic runs more continuously while the machine is working, while step modes refer to functions that need to be triggered by an order (think sequential order); this often means pushing a button.

PLC Industry Trends

Since there’s a growing demand for automation, PLC skills are highly sought after by a number of different industries. This shouldn't be a surprise to anyone since automation is becoming more prevalent in everyday life, from self-checkout stations at the grocery store to large machines used in manufacturing and production. Because of these trends, educators are responding to this industrial shift with more post-secondary institutions offering PLC training programs for a world of automation.

Comments

PLC/HMI Programming & wiring

Submitted by Joseph Fatokun on Tue, 02/21/2023 - 19:54

I want to learn more about PLC & HMI Programming.

One module specifically…

Submitted by iris on Wed, 02/22/2023 - 08:06

One module specifically will provide an introduction to PC-based programming terminals and their application in advanced PLC systems. The module also covers software used in programming terminals and describes the basic operating principles of host computer systems. In addition, an introduction to HMI programming terminals is presented with an emphasis on PLC-based systems. Peripheral devices are also described in detail including memory storage and data transfer systems.

Please contact a Program Consultant, toll-free at 1-888-553-5333, to discuss the PLC program in greater detail.

Programming Language

Submitted by Aladeyelu Adeniyi on Tue, 03/28/2023 - 04:24

I am electrical technician with more 20 years experience. I wants to know how to write programming and become expert in it.

Thanks

Our PLC Technician programs …

Submitted by iris on Wed, 03/29/2023 - 08:19

Our PLC Technician programs (PLC and PLC Technician II) are focused on teaching you the ladder logic programming along with the installation and maintenance of PLC systems. Your Electrical background will be a great help to you in understanding the basics of relay circuits but having said that we do not expect any kind of background in PLCs or Electrical engineering. Our programs are designed to teach the basics first and will prepare you to become an expert in programming, testing, and debugging ladder logic programs using the industry standard simulation tools that emulates the real-world manufacturing environments.

To further discuss about the PLC Technician programs in detail, please do not hesitate to speak to a Program Consultant toll-free at 1-888-553-5333.

Our PLC programs are easy-to…

Submitted by iris on Fri, 01/12/2024 - 11:48

Our PLC programs are easy-to-use, computer-based, self-paced and are designed to put you in charge of your technical training. The interactive curriculum, simulation software, student support and online exams provide a completely flexible learning framework that allows you to learn, study, practice and complete the program on your terms. For more further assistance contact a Program Consultant toll-free at 1-888-553-5333.

I wish to understand to write softwares of PLCs and how they work with different machines and applications